This week we will showcase our T-27 Tank. Please watch the video below and do not hesitate to contact us if you have any questions regarding any of our products.

Author: Monica Polden

PRODUCT VIDEO PRESENTATION – T-46 Tank

This week we will showcase our T-46 Tank. Please watch the video below and do not hesitate to contact us if you have any questions regarding any of our products.

PRODUCT VIDEO PRESENTATION – Compactor

This week we will showcase our Compactor. Please watch the video below and do not hesitate to contact us if you have any questions regarding any of our products.

PRODUCT VIDEO PRESENTATION – Half Height Basket

This week we will showcase our Half Height Basket. Please watch the video below and do not hesitate to contact us if you have any questions regarding any of our products.

PRODUCT VIDEO PRESENTATION – Basket

This week we will showcase our Offshore Basket. Please watch the video below and do not hesitate to contact us if you have any questions regarding any of our products.

Product Video Presentation – Mini Container

Starting today and every Tuesday moving forward we will be sharing a product presentation video series with you.

First up is our Mini Container. Please watch the video below and do not hesitate to contact us if you have any questions regarding any of our products.

*Please note that the product shown in this video is the standard for the European region. Regional variations may apply to certain products.

Wishing you all the best for the holiday season!

Double standards on offshore lifting equipment

As responsible for Modex AsiaPac operations I frequently visit major offshore supply bases and oilfield service workshops in the region. Many of these bases and workshops are operated by international companies with high safety requirements. When you enter the office reception, you are welcomed by nice, big health and safety signboards which emphasise the importance of safe operations. As a supplier, we have agreed to comply with the highest international industry standards for offshore lifting equipment, DNV 2.7-1.

However, when I pass through the reception and visit the workshops and yards, I am taken aback by the amount of old, rusty and non-standard lifting equipment used in daily offshore operations by the same international companies in Asia. In our industry it is estimated that more than half of the offshore lifting equipment in Asia is non-DNV certified, if certified at all.

Some may argue that DNV-certified equipment is too expensive compared to local manufactured non-certified equipment, but at what risk? As production cost of DNV certified equipment has been dramatically reduced by moving production to China, I think the cost saving argument is no longer valid.

We are in the middle of a major downturn in the oil industry and it is a great opportunity to clean out outdated lifting equipment and replace it with new cost efficient DNV 2.7-1 certified equipment that we manufacture in-house in China. Modex supplies new equipment for sales, rental or leasing.

Per Ingar Amlie – Regional Director, Asia Pacific

How we help our clients stay profitable without losing business

Everyone on the supply side of the offshore container business are facing the incredible price pressure from clients these days. We are fighting for cents per day while we hear stories that the same equipment had to be airfreighted to site to meet a deadline due to miscalculation in logistic planning. How can we as suppliers take a more active role in our clients cost reduction programs?

My first job after graduation was with the Norwegian Trade Council in Stockholm. One of our major projects was to develop industrial relationships between Norwegian suppliers and Swedish industrial super majors like ABB, Volvo, Ericsson and Scania. Swedish industry had been defending their market position against Asian competitors for more than 20 years at that time. Prices were falling and their market environment was not so different from what we experience in the oil industry in the current downturn.

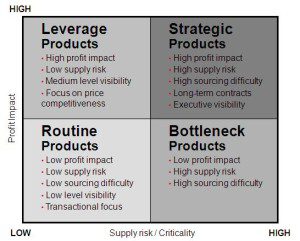

The supply chain directors I met in Swedish industry had an analytical approach to total cost reductions, and I believe we can apply the same models in the offshore service industry. To move more risk to suppliers is not how the total value chain becomes more efficient or competitive. We have to analyse the business relationship along two axes.

X-axis: How critical is the supplier to our operation or Production?

Y-axis: How high is the relative total spending on the supplier?

I believe partnerships with a closer integration of operations and operation planning is key to major cost reductions. By doing joint product development, planning and optimisation, we can reduce cost and improve efficiency through the whole logistic chain and it will benefit all parties rather than a zero sum game where two parties are not increasing total value, but only fighting for a share of limited value.

Modex uses various types of tracking solutions and advanced database fleet management systems which we integrate with our clients planning and management systems. Automated solutions increase control and reduce risk of human errors. We achieve substantial savings on both sides of the table as equipment arrives in time to get the job done. Operations have full control on location of parts during transport and any disruption can be handled immediately.

Contact us if you want to know more about how we can improve your offshore supply operations.

Per Ingar Amlie – Regional Director, Asia Pacific